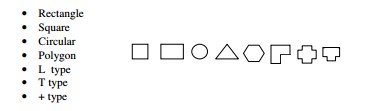

Basic Design Concepts in Limit State Method

Introduction to Limit State Method

The Limit State Method is a design approach used in structural engineering to ensure the safety and serviceability of structures. It involves considering two critical limit states: the ultimate limit state (ULS) and the serviceability limit state (SLS). These states define conditions where the structure is on the verge of failure or causing discomfort to occupants.

Definition of Limit States

A limit state is a condition of impending failure beyond which the structure is deemed unsafe or unserviceable. The two primary limit states are:

Ultimate Limit State (ULS): Represents the point where the structure may experience collapse, buckling, sliding, or other failure modes.

Serviceability Limit State (SLS): Marks the stage where the structure begins to cause discomfort or malfunction, such as excessive deflection, crack widths, vibration, or leakage.

Safety Factors in Limit State Design

Safety factors are introduced to ensure that the structure remains safe and serviceable under various conditions. These factors are incorporated into the resistance and load equations, and they are denoted as Φ (resistance factor) and γ (load factor).

The resistance equation is expressed as:

Where:

- is the nominal or characteristic value of resistance.

- is the nominal or characteristic value of load effect.

- is the resistance factor.

- is the load factor.

Nominal or Characteristic Values

Nominal values are obtained from material properties specified by the code. For example, the characteristic strength of steel () and concrete ().

Partial Safety Factors

The code introduces partial safety factors to account for uncertainties. For resistance, concrete () and steel () have their factors, while for loads, dead load (), live load (), and wind/earthquake load () each have their factors.

Safety Factor Application

Partial safety factors are applied to the material properties and loads to ensure that the structure remains safe and serviceable. For concrete, the code accounts for the variable nature of its qualities by using . Steel safety factors consider both linear elastic and plastic behavior.

Values for Partial Safety Factors

For ultimate limit states:

- (concrete)

- (steel)

For serviceability limit states:

- (concrete)

- (steel)

Load Combination for Ultimate Limit States

Various combinations of loads are considered, and the maximum value among them is chosen to calculate the ultimate load.

Load Combination for Serviceability Limit States

Similar load combinations are considered for serviceability limit states, but with different partial safety factors.

Materials: Concrete and Steel

Material design values are obtained from characteristic curves representing stress and strain relationships. The code specifies values for partial safety factors for concrete and steel based on these curves.

In the next chapter, we will delve into the analysis of sections using the Working Stress Method, exploring the practical application of these fundamental concepts.