Classification of columns

A column is defined as a compression member, the effective

length of which exceeds three times the least lateral dimension.

Compression members, whose lengths do not exceed three times

the least lateral dimension, may be made of plain concrete.

A column forms a very important component of a structure.

Columns support beams which in turn support walls and slabs.

It should be realized that the failure of a column results in the

collapse of the structure. The design of a column should therefore

receive importance.

Introduction:

A column is a vertical structural member supporting axial

compressive loads, with or without moments. The cross-sectional

dimensions of a column are generally considerably less than its height.

Columns support vertical loads from the floors and roof and transmit

these loads to the foundations. The more general terms compression

members and members subjected to combined axial load and

bending are sometimes used to refer to columns, walls, and members

in concrete trusses or frames. These may be vertical, inclined, or horizontal.

A column is a special case of a compression member that is vertical.

Stability effects must be considered in the design of compression members.

Classification of columns

A column may be classified based on different criteria such as:

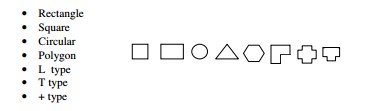

1.Based on shape

I. Rectangle

Square

III. Circular

IV. Polygon

V. L type

VI. T type

VII. + type

2.Based on slenderness ratio or height

Short column and Long column or Short and Slender Compression Members

A compression member may be considered as short when both the slenderness

ratios namely lex/D and ley/b are less than 12: Where

lex= effective length in respect of the major axis,

D= depth in respect of the major axis,

ley= effective length in respect of the minor axis, and

b = width of the member.

It shall otherwise be considered as a slender or long compression member.

The great majority of concrete columns are sufficiently stocky (short) that

slenderness can be ignored. Such columns are referred to as short columns.

Short column generally fails by crushing of concrete due to axial force.

If the moments induced by slenderness effects weaken a column appreciably,

it is referred to as a slender column or a long column. Long columns

generally fail by bending effect than due to axial effect. Long column

carry less load compared to long column.

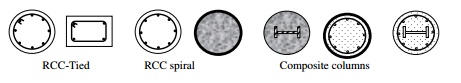

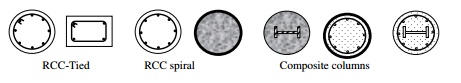

3.Based on pattern of lateral reinforcement

� Tied columns with ties as laterals

� columns with Spiral steel as laterals or spiral columns

Majority of columns in any buildings are tied columns.

In a tied column the longitudinal bars are tied together with smaller

bars at intervals up the column. Tied columns may be square, rectangular,

L-shaped, circular, or any other required shape. Occasionally, when high

strength and/or high ductility are required, the bars are placed in a circle,

and the ties are replaced by a bar bent into a helix or spiral. Such a

column, called a spiral column. Spiral columns are generally circular,

although square or polygonal shapes are sometimes used. The spiral acts to

restrain the lateral expansion of the column core under high axial loads and,

in doing so, delays the failure of the core, making the column more ductile.

Spiral columns are used more extensively in seismic regions. If properly

designed, spiral column carry 5% extra load at failure compared to similar

tied column.

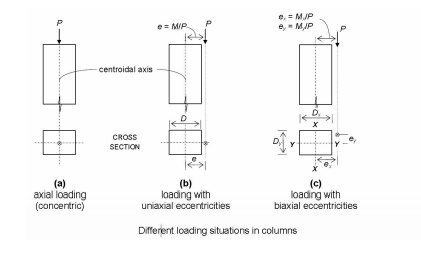

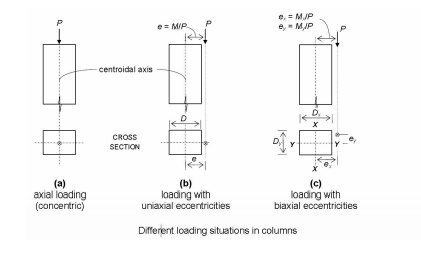

4.Based on type of loading

� Axially loaded column or centrally or concentrically loaded column (Pu)

� A column subjected to axial load and unaxial bending (Pu + Mux) or (P + Muy)

A column subjected to axial load and biaxial bending (Pu + Mux + Muy)

5. Based on materials

Timber, stone, masonry, RCC, PSC, Steel, aluminium , composite column

A column is defined as a compression member, the effective

length of which exceeds three times the least lateral dimension.

Compression members, whose lengths do not exceed three times

the least lateral dimension, may be made of plain concrete.

A column forms a very important component of a structure.

Columns support beams which in turn support walls and slabs.

It should be realized that the failure of a column results in the

collapse of the structure. The design of a column should therefore

receive importance.

Introduction:

A column is a vertical structural member supporting axial

compressive loads, with or without moments. The cross-sectional

dimensions of a column are generally considerably less than its height.

Columns support vertical loads from the floors and roof and transmit

these loads to the foundations. The more general terms compression

members and members subjected to combined axial load and

bending are sometimes used to refer to columns, walls, and members

in concrete trusses or frames. These may be vertical, inclined, or horizontal.

A column is a special case of a compression member that is vertical.

Stability effects must be considered in the design of compression members.

Classification of columns

A column may be classified based on different criteria such as:

1.Based on shape

I. Rectangle

Square

III. Circular

IV. Polygon

V. L type

VI. T type

VII. + type

2.Based on slenderness ratio or height

Short column and Long column or Short and Slender Compression Members

A compression member may be considered as short when both the slenderness

ratios namely lex/D and ley/b are less than 12: Where

lex= effective length in respect of the major axis,

D= depth in respect of the major axis,

ley= effective length in respect of the minor axis, and

b = width of the member.

It shall otherwise be considered as a slender or long compression member.

The great majority of concrete columns are sufficiently stocky (short) that

slenderness can be ignored. Such columns are referred to as short columns.

Short column generally fails by crushing of concrete due to axial force.

If the moments induced by slenderness effects weaken a column appreciably,

it is referred to as a slender column or a long column. Long columns

generally fail by bending effect than due to axial effect. Long column

carry less load compared to long column.

3.Based on pattern of lateral reinforcement

� Tied columns with ties as laterals

� columns with Spiral steel as laterals or spiral columns

Majority of columns in any buildings are tied columns.

In a tied column the longitudinal bars are tied together with smaller

bars at intervals up the column. Tied columns may be square, rectangular,

L-shaped, circular, or any other required shape. Occasionally, when high

strength and/or high ductility are required, the bars are placed in a circle,

and the ties are replaced by a bar bent into a helix or spiral. Such a

column, called a spiral column. Spiral columns are generally circular,

although square or polygonal shapes are sometimes used. The spiral acts to

restrain the lateral expansion of the column core under high axial loads and,

in doing so, delays the failure of the core, making the column more ductile.

Spiral columns are used more extensively in seismic regions. If properly

designed, spiral column carry 5% extra load at failure compared to similar

tied column.

4.Based on type of loading

� Axially loaded column or centrally or concentrically loaded column (Pu)

� A column subjected to axial load and unaxial bending (Pu + Mux) or (P + Muy)

A column subjected to axial load and biaxial bending (Pu + Mux + Muy)

5. Based on materials

Timber, stone, masonry, RCC, PSC, Steel, aluminium , composite column